For your Industrial CNC Router to cut accurately, the motors need to be tuned. Basically this means that every step sent from the computer to the machine needs to translate correctly to the units you measure with (inches or millimeters.) When motors are tuned properly the machine will cut the distance your job requires.

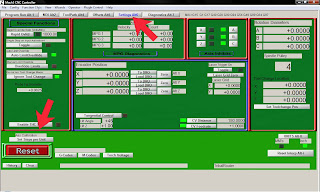

You will start out with your X and Y axis at around 2,000 steps per unit. And your Z axis at around 4,000 steps per unit. These are ballpark numbers, so some tuning is required. Fortunately Mach has an automated motor tuning feature that will make this easy. Go to the "SETTINGS" tab and you'll find it right over the RESET button.

Note: You will need either a digital movement gauge or a tape measure before going further.

Click on the SET STEPS PER UNIT button, and a pop up window will appear asking which axis you would like to calibrate.

Select an axis

Another window will then pop up asking how far you would like each axis to move.

Enter a number (inches)

Be advised that when you enter a number it will then move the spindle that distance (or what it thinks is that distance.) The longer the distance the more any inaccuracy will be noticeable, so use a large number but make sure the spindle is far enough to the the left or front that it can travel that distance.

As soon as the movement is done, another window will appear to ask you how far the machine actually moved.

Enter in the actual distance it moved. Make sure to add the diameter of your bit.

Mach will then suggest a number for your steps per unit. Accept it and Mach will automatically calibrate the axis to that setting.

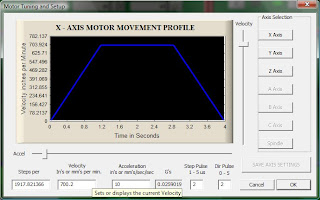

You can also change the setting manually by going to Config/Motor Tuning

You can also change your travel speed here by adjusting the sliders on the bottom and right side of the chart.

No comments:

Post a Comment