You'll also want to make sure that you have Mach 3 set to find your new card. If you open Mach and Look in Config/Ports and Pins. By default Mach will assign 0x378, which is where a native parallel port would be.

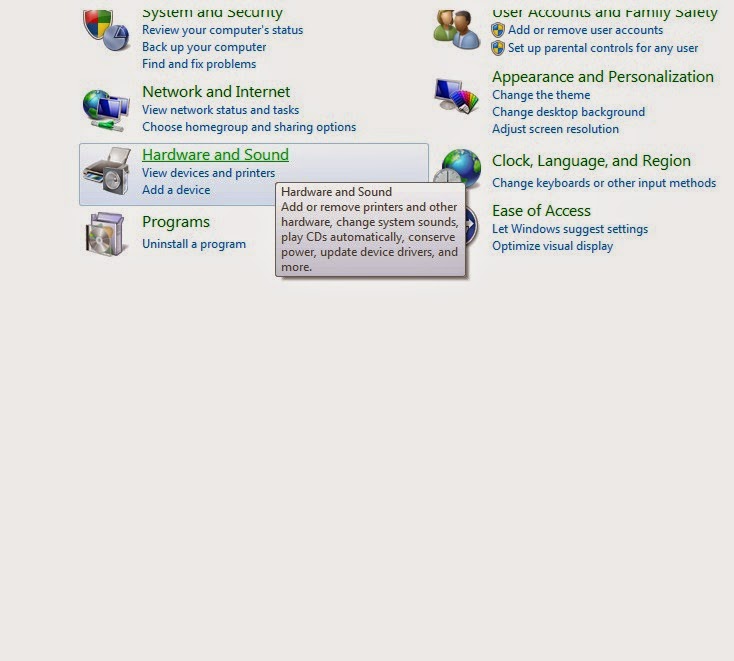

A new card is not likely to have this address, so you'll have to find out what it is. You can find it by going to your Windows Control Panel. Clack on "Hardware and Sound" and you should see an option for "Device Manager" Clicking on this will give you a list of your devices, including your PCI Card. Right Click on the PCI Card in the list and choose "Properties" you should see your I/O Range. Select the first four characters and enter them into Mach 3 as your port address with 0x added in front of them. Mach should now be communicate with your new PCI card.

Control panel/Hardware and Sound

Devices and Printers/Device Manager

Device Manager/PCI Parallel Port/Properties

In this case. your address would be 0xDCC8.

Enter it into Mach 3 Config/Ports and Pins/Port Setup and Axis Selection.